CUSTOM SNOWBOARDS

Yes, that’s right, we do it right here in America, from start to finish, with the hands of craftsmen for over 25 years. When we build your custom snowboards you can count on quality!

Not only do we have the experience, but we also have an understanding of materials, shapes, and the details required to execute the production of high-quality, high-performing snowboards. Whether you’re looking for a snowboard for personal use or for promotional purposes, our custom snowboards are a perfect choice. Each board is made from the finest materials and is designed to meet the highest standards of quality snowboarding, providing you with a truly unforgettable riding experience. Browse our selection of custom snowboards today and discover the perfect board for your needs!

Below is a brief video explaining the different options for corporate and promotional programs.

To gain corporate access to our site, go register here as a corporate account. This will give you access to current pricing on all our products, in addition to full access to our online product design tool. This will allow you to generate mock-ups right on our site.

Board Features

Request More Info –

If we already have your contact info, filling out the form will just update it.

Artwork Instructions

Top Print Method

Digital Sublimation. Most of our snowboard tops are printed using a digital sublimation print process. In order to get the best output, you should design in CMYK using a vector design program. If your design is comprised of photos or raster images you should design in CMYK with a resolution of 150dpi or higher, and be sure that all photos are to scale. Be sure to download any templates you may need.

The best file formats are .AI, .PSD, .EPS, .TIFF, .PNG anything uncompressed.

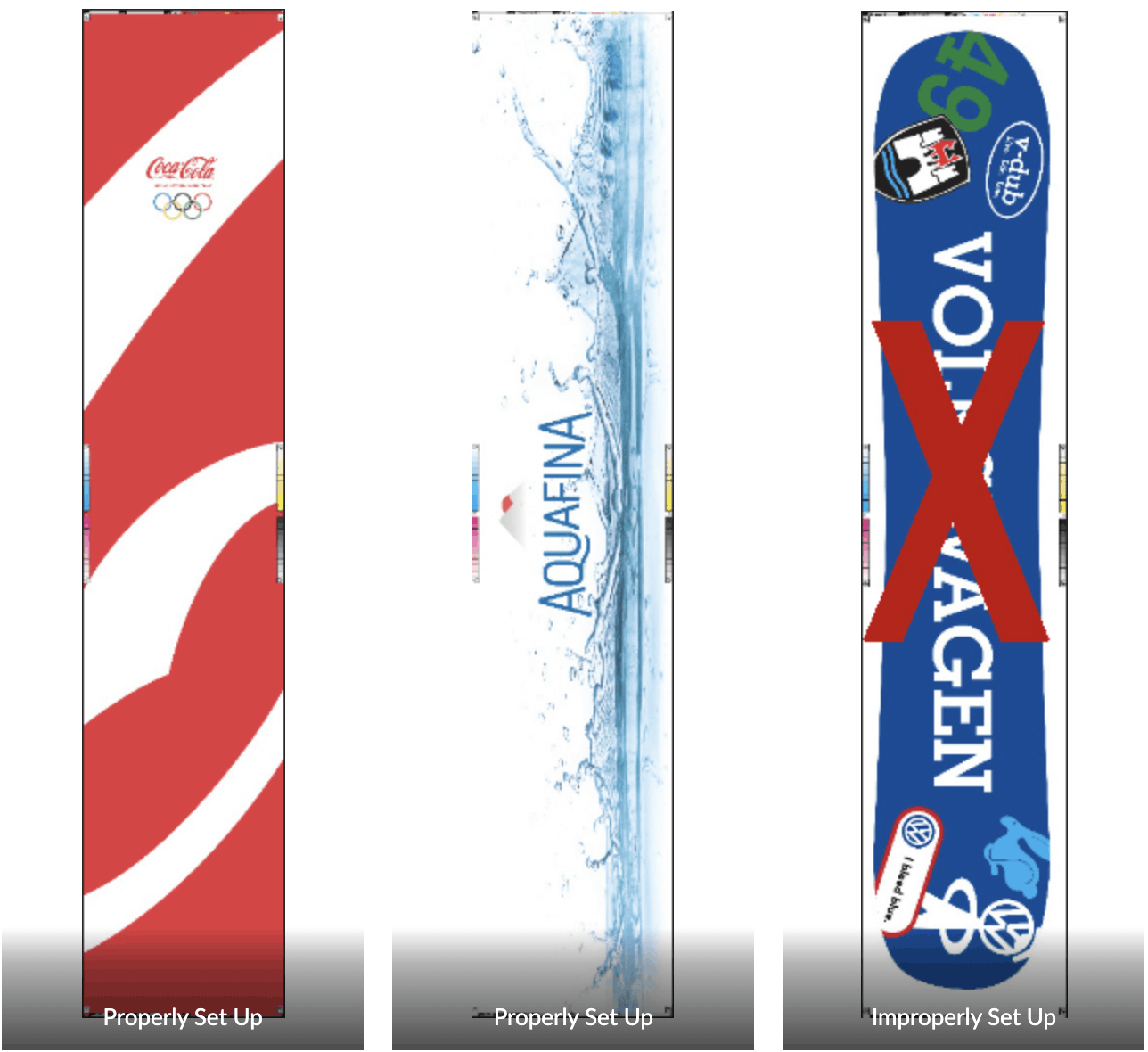

The design templates are laid out in a rectangle with the outline of the snowboard as a layer. Be sure to design on the layer labeled “artwork” and leave the template layer alone so we can turn it off when printing. DO NOT CROP THE IMAGE TO THE SHAPE OF THE BOARD! We need the bleed in order to ensure all design elements are correct. See examples:

Base Print Method

Screenprint. Most of our snowboard bases are printed using a screen print method. We use screen printing because of the opacity and bonding characteristics of the inks used. For best results, a two-color screenprint is best, for a bit extra cost we can make more passes if your design requires it.

Basically use the same methods as the top, but just use fewer colors and a simpler design. Unlike the tops, we print on the INSIDE of the materials, the side that is getting bonded to. You will look at your image through the 1.2mm thickness of the clear materials.

The best file formats are .AI, .PSD, .EPS, .TIFF, .PNG anything uncompressed.

Follow American Gear Company On Instagram

New “Ready to Ship” model in production now and ready for shipping 6.1.24 in a limited run. Powered by an i5 pc with 16gb ram, genuine Suzo Happ buttons and joysticks, included trackball and spinner. 32” viewsonic computer screen, real wood, plexiglass. Pixelcade and Sinden lightgun ready. 3 year warranty and made by a company that’s been in business for 27 years.

#retrogaming #sindenlightgun #usamade #agcarcade #pixelcade @suzohapp

Super stoked for this partnership….stay tuned, launching very soon! Sign up to be notified when we drop our first limited qty production run.

https://www.coleco.vision

#coleco #colecovision #retrogamer #retrogaming #opensource #arcadegames #80sarcadegames

The teaspoon wakesurf model is ready to order. Built in two artwork variations this hand glasses surf is available in 3 sizes, features a triple concave base and nose rocker.

https://americangearcompany.com/product/humanity-teaspoon-wakesurfer/

#wakesurf

#stgeorgeutah

#agcsurf

Profile series arcade now available in Toffee stain.

#agcarcade #retroarcade #arcadefurniture #stgeorgeutah

Can’t argue the light up buttons look sick on the profile series machine!

#agcarcade

#retroarcade

This would look great in your house! Premium everything and includes a lifetime of fun at no additional cost.

#agcarcades

#retrogaming

#stgeorgeutah

#sindenlightgun

@pixelcade_led_marquee

@glensretro

https://americangearcompany.com/product/retro-arcade-brushed-aluminum/

You don’t need to ride what everyone else is riding, be unique and design your own board!

www.americangearcompany.com

#customwakesurfboards #agcwakesurf #stgeorgeutah

2024 Humanity skim style wakesurfer ready to ship. Humanity is a small Niche brand of American Gear Company. These are premium wakesurfers made by hand with top shelf materials all done in Utah.

https://americangearcompany.com/product/humanity-phazer-wakesurf/

#wakesurf

#wakesurfboard

#stgeorgeutah

Each year our town does a parade of homes showcasing newly built houses. We made this beauty for an entry this year. White oak, black trim, super slick! We can make a functional piece of furniture for you also! This is how you get your wife to say YES to an arcade machine. This build has lightguns, pixelcade, spinners and driving wheels that go on the spinners.

#retrogaming

#agcarcade

#stgeorgeutah

#paradeofhomes

www.americangearcompany.com

Don’t spend the money on a machine that just looks good, it needs to feel good also. We use premium wood, parts and software to give you the best arcade experience possible. 5 year warranty and software updates for life.

#realwood

#suzohapp

#ultimarc

#viewsonic

First look at Xbox on our new PC option AGC arcade. PS2 and PS3 are also configured. D working. #agcarcade #retrogaming

HOURS

Monday-Friday: 8am - 7pm

Saturday: 9am - 5pm

Sunday: Closed