SURFBOARDS

Hand Glassed, High-Performance Surfboards

Hand glassed surfboards utilizing polyurethane cores, wood stringers, and premium epoxies represent a blend of traditional craftsmanship and modern technology, resulting in high-performance boards with exceptional durability and aesthetic appeal.

Polyurethane cores provide the foundational structure of the surfboard, offering a balance of lightweight construction and resilience to withstand the rigors of surfing. The use of wood stringers enhances the board’s strength and responsiveness, adding flex and torsional rigidity while maintaining a natural aesthetic.

Premium resins are employed in the lamination process to ensure superior bonding and water resistance, enhancing the longevity and performance of the surfboard. These resins provide a strong, lightweight coating that protects the board from delamination and maintains its structural integrity even in challenging conditions.

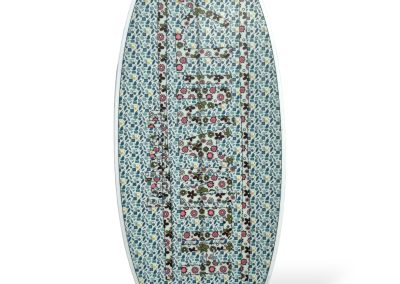

Moreover, one of the distinguishing features of these surfboards is the ability to digitally print super opaque, photorealistic images directly onto the board’s surface. This innovative printing technique allows for intricate designs, vibrant colors, and high-resolution graphics to be applied, transforming the surfboard into a personalized work of art. Whether it’s capturing breathtaking landscapes, showcasing artistic illustrations, or expressing individual creativity, this customization option adds a unique touch to each board, further enhancing its visual appeal and making it stand out in the water.

New “Ready to Ship” model in production now and ready for shipping 6.1.24 in a limited run. Powered by an i5 pc with 16gb ram, genuine Suzo Happ buttons and joysticks, included trackball and spinner. 32” viewsonic computer screen, real wood, plexiglass. Pixelcade and Sinden lightgun ready. 3 year warranty and made by a company that’s been in business for 27 years.

#retrogaming #sindenlightgun #usamade #agcarcade #pixelcade @suzohapp

Super stoked for this partnership….stay tuned, launching very soon! Sign up to be notified when we drop our first limited qty production run.

https://www.coleco.vision

#coleco #colecovision #retrogamer #retrogaming #opensource #arcadegames #80sarcadegames

The teaspoon wakesurf model is ready to order. Built in two artwork variations this hand glasses surf is available in 3 sizes, features a triple concave base and nose rocker.

https://americangearcompany.com/product/humanity-teaspoon-wakesurfer/

#wakesurf

#stgeorgeutah

#agcsurf

Profile series arcade now available in Toffee stain.

#agcarcade #retroarcade #arcadefurniture #stgeorgeutah

Can’t argue the light up buttons look sick on the profile series machine!

#agcarcade

#retroarcade

This would look great in your house! Premium everything and includes a lifetime of fun at no additional cost.

#agcarcades

#retrogaming

#stgeorgeutah

#sindenlightgun

@pixelcade_led_marquee

@glensretro

https://americangearcompany.com/product/retro-arcade-brushed-aluminum/

You don’t need to ride what everyone else is riding, be unique and design your own board!

www.americangearcompany.com

#customwakesurfboards #agcwakesurf #stgeorgeutah

2024 Humanity skim style wakesurfer ready to ship. Humanity is a small Niche brand of American Gear Company. These are premium wakesurfers made by hand with top shelf materials all done in Utah.

https://americangearcompany.com/product/humanity-phazer-wakesurf/

#wakesurf

#wakesurfboard

#stgeorgeutah

Each year our town does a parade of homes showcasing newly built houses. We made this beauty for an entry this year. White oak, black trim, super slick! We can make a functional piece of furniture for you also! This is how you get your wife to say YES to an arcade machine. This build has lightguns, pixelcade, spinners and driving wheels that go on the spinners.

#retrogaming

#agcarcade

#stgeorgeutah

#paradeofhomes

www.americangearcompany.com

Don’t spend the money on a machine that just looks good, it needs to feel good also. We use premium wood, parts and software to give you the best arcade experience possible. 5 year warranty and software updates for life.

#realwood

#suzohapp

#ultimarc

#viewsonic

First look at Xbox on our new PC option AGC arcade. PS2 and PS3 are also configured. D working. #agcarcade #retrogaming

HOURS

Monday-Friday: 8am - 7pm

Saturday: 9am - 5pm

Sunday: Closed